How swirling the slurry changes riser vibration in deep-sea mining

Title: Experimental study on vibration responses of flexible riser transporting spiral flow in deep sea mining: Part II – solid-liquid two-phase transportation

Author / Sponsor: Jiayu Zhang, Nian-Zhong Chen, Svein Sævik, Aichun Feng; Tianjin University, NTNU, Shanghai Jiao Tong University; experiments run on SJTU’s Fengxian Base deep-sea mining transport system.

Date: December 13, 2024; Marine Structures 101 (2025), article 103757.

Report Length: 23 pages

BLUF: In controlled experiments with particle-laden slurry, straight flow made the flexible riser bend mid-span and oscillate as density waves passed, while spiral flow produced a more even internal pressure field that suppressed bending and shifted vibrations toward higher-order modes with stronger nonlinear features.

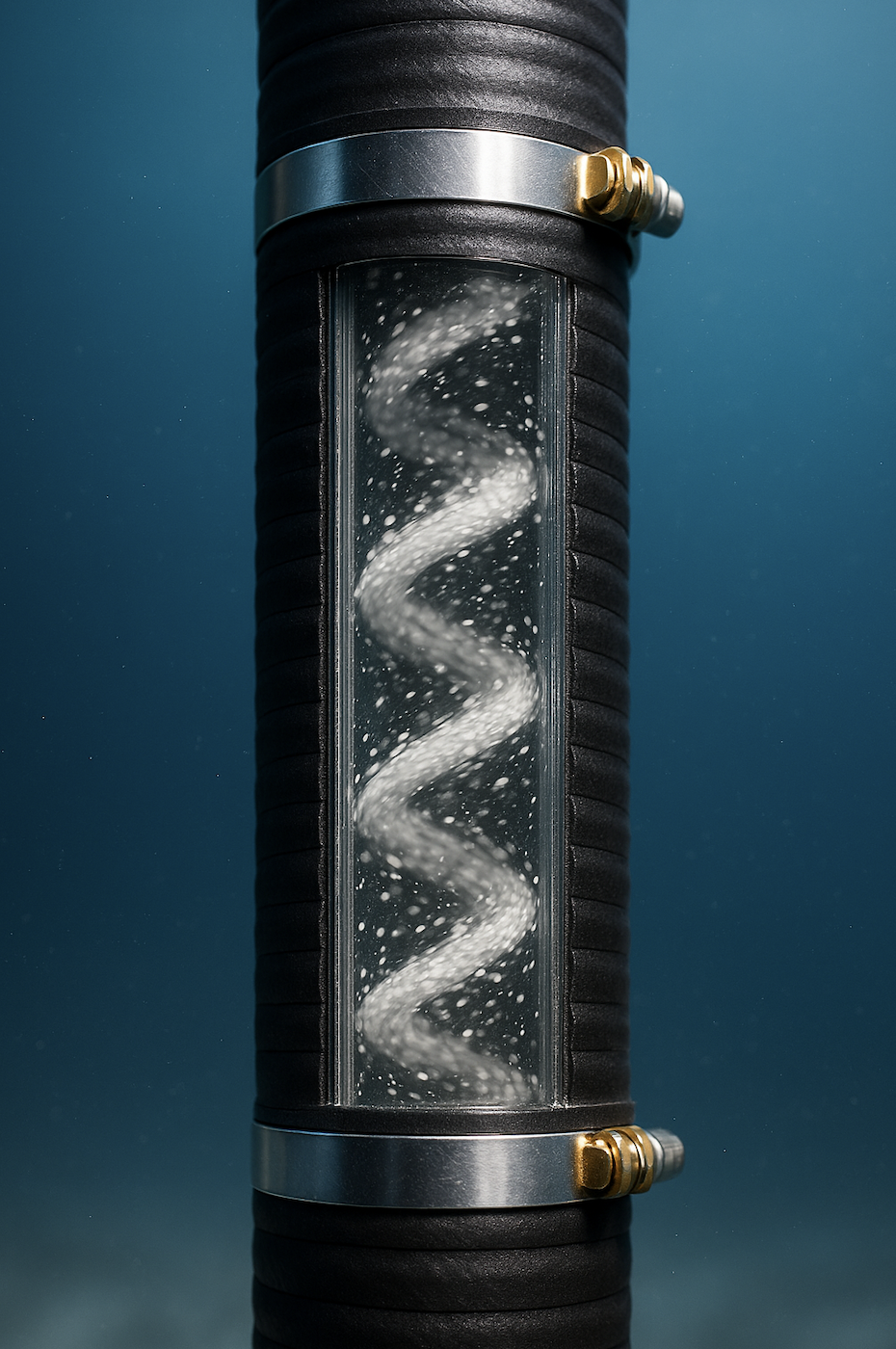

The facility pumps water and glass particles into a flexible, steel-wire-reinforced rubber riser and can impart circumferential swirl up to 17 m per second while setting axial transport between 2 and 4 m per second. Motion is captured by a dual-camera, non-contact optical system with roughly 0.012 mm accuracy and mean axis errors near 1 percent.

Data are filtered and converted to the frequency domain using Fourier transforms and a modified Welch method to identify dominant modes. The natural frequencies shift with internal flow conditions; the baseline first natural frequency in still water is 0.698 Hz.

For straight two-phase flow the riser shows an immediate mid-span bend and, once density waves form, periodic large-amplitude flutter and noticeable deformation. In the specific 2.5 m per second case, the spectrogram in Fig. 6 shows energy near 0.5 Hz with water that shifts to about 0.14 Hz during particle transport, with periodic swings of roughly 5-8 mm depending on direction.

As transport velocity rises from 2.5 to 4 m per second, RMS amplitudes grow along the riser span. Increasing average internal flow density from 1,047 to 1,235 kg per cubic meter also raises vibration frequency and amplitude. The response exhibits a lock-in phenomenon where frequency stays near a natural mode while amplitude scales with velocity.

With spiral flow the riser deforms less at the same axial speeds because dynamic pressure is more evenly distributed and lateral forces are reduced by flow convergence toward the axis. Vibrations concentrate around the second-order frequency near 0.44 to 0.5 Hz, and turbulence broadens participation as swirl increases. Fig. 12 shows a first-mode pattern in x, a third-mode in y, and the emergence of a second-mode in z near 11.5 m per second swirl; at 12.5 to 13.5 m per second resonance and unstable patterns appear.

The modal frequency table reports, for example, 0.14 and 0.30 Hz for straight flow at 3 m per second with 1235 kg per cubic meter, and 0.11 and 0.44 Hz for spiral flow at 3 m per second with the same density. The paper models density waves as regular traveling waves and shows that spiral flow suppresses their transfer along the riser, while straight flow is directly excited by them.

Designers can exploit spiral flow to reduce bending and density-wave-driven periodic swing during hydraulic lift, while accounting for the multi-mode and sometimes unstable response that appears at high swirl. The evidence here is experimental and grounded in full-field motion measurements on a large rig.