The 5-Step Journey Up a 4 km Riser

1. Slurry Pick-Up

On the seabed a robot crawler sweeps loose nodules into a hopper. Water jets mix in seawater, turning rocks and mud into a heavy “milkshake” called slurry.

2. Booster Pump Launch

A turbo-pump the size of a small car sits just above the crawler. It pressurises the slurry so it can climb a four-kilometre steel pipe, much like an elevator motor.

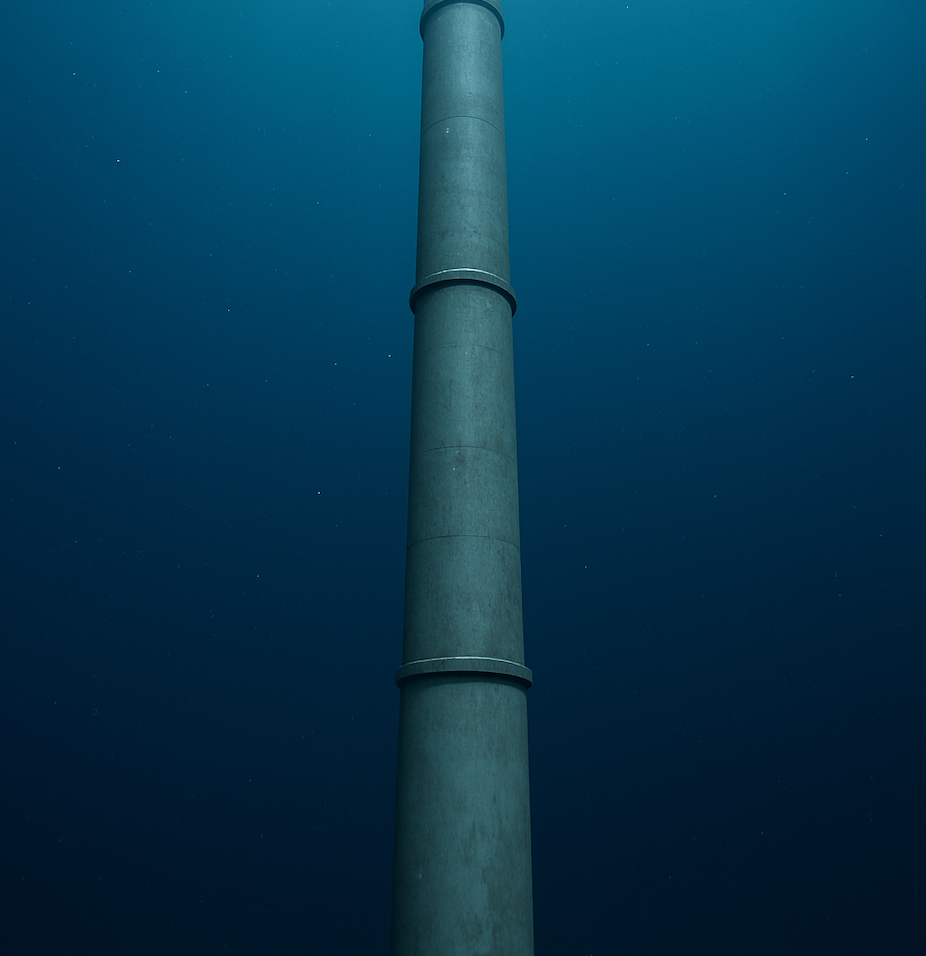

3. Vertical Climb

The slurry shoots up a 40-centimeter-wide riser. Pipe sections get thicker near the surface to survive bending from waves and currents. Flexible joints every few hundred meters absorb ship heave so nothing snaps.

4. Deck Transfer

At the ship, the flow curves into vibrating screens. Nodules land on conveyor belts; seawater drains through mesh panels. Operators track flow and pressure with real-time sensors.

5. Water Return Loop

80 - 90 % of the carrier water is filtered and pumped back down another pipe to ~1,000 m depth, deep enough to keep the surface clear, shallow enough to save energy. The now-damp nodules move to covered holds for shipment to shore.

From mud floor to deck takes under an hour, monitored the whole way by cameras and pressure gauges.