What oil and gas ships can teach us about building deep-sea mining vessels

Title: Exploring Vessels from the Offshore Oil and Gas Industry in Design of Deep-Sea Mining Vessels

Author / Sponsor: Astrid V. Solheim; Per O. Brett; Jose J. G. Agis; Donna Rhodes; Adam Ross; Bjørn E. Asbjørnsletten. Affiliations: NTNU Department of Marine Technology, Ulstein International AS, and MIT SEAri.

Date: February 2025, Journal of Ship Production and Design, Vol. 41, No. 1, pp. 14 to 26.

Report Length: 13 pages

BLUF: Using the Responsive Systems Comparison method, the authors test thousands of mining-ship design options derived from offshore vessel technologies and show that a small set of configurations delivers the best utility-to-cost tradeoff, with mission equipment dominating CAPEX and well-chosen deck area and deadweight enabling robust performance across scenarios.

The study explores transferring mature offshore vessel capabilities into deep-sea mining and evaluates value robustness rather than prescribing a single optimal ship. Two explicit stakeholders shape value attributes: a mining company focused on mineral supply, competitiveness, and responsibility, and a vessel operator focused on flexibility, profitability, and production continuity. These attributes are operationalized into physical features such as deadweight, deck area, riser length, LARS choice, STS method, and enclosed derrick for crew safety.

The design space includes collector type, free deck area from 2000 to 5500 m², riser and lift system (open or enclosed derrick), riser length from 0 to 6500 m, station-keeping at DP2 or DP3, storage from 39,000 to 120,000 t, LARS via crane or A-frame, and STS via conveyor boom or floating hose, with Nautilus values listed for comparison. CAPEX is built from a fixed 200 MUSD ship construction cost plus 6 MUSD dewatering and 40 MUSD for two offshore cranes, with DP3 adding 3 MUSD and an enclosed derrick adding about 0.7 MUSD for extra steel. The utility function aggregates attribute utilities with epoch scaling. A footprint penalty lowers utility for tool choices assumed to create more seabed plume.

Epoch variables represent resource type, water depth from 1000 to 6500 m, and sea state at high, medium, or low, yielding 108 combinations that stress designs across plausible futures. In Epoch 28, representing sulfides in the Norwegian Sea at 2300 m, a legacy Nautilus concept sits well off the Pareto front due to high seafloor tool cost and lower utility linked to footprint.

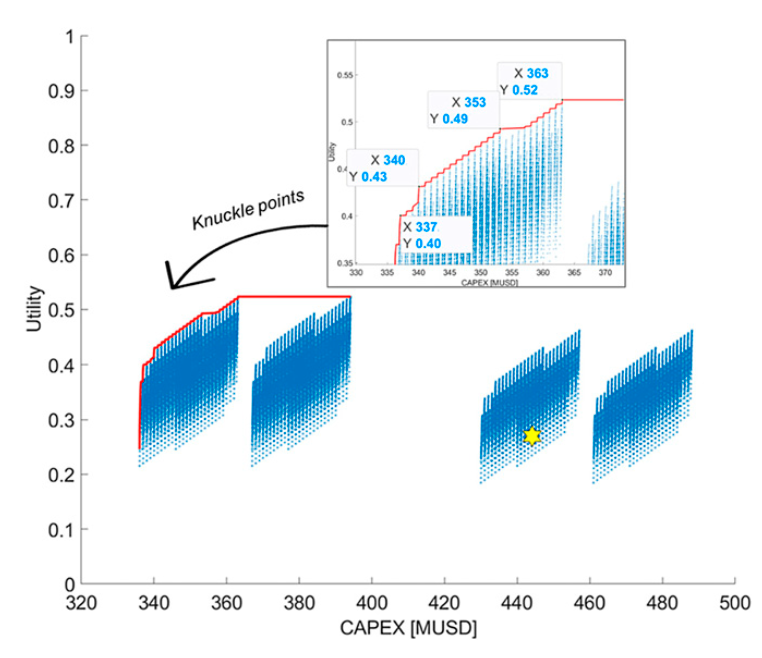

Across many epochs, the study concentrates on the left cluster of solutions where utility rises faster than cost and identifies three knuckle-point designs that consistently balance capability and affordability. These designs push deck area and deadweight to their maximum values to support equipment handling and storage.

Pareto designs in Table 3:

- Design I: Enclosed derrick, A-frame LARS, DP2, 5500 m² deck, 120,000 t deadweight, floating hose STS, riser depth set to 0 with riser pipes carried by a support vessel; CAPEX 337.1 MUSD; mean utility 0.46.

- Design II: Enclosed derrick, A-frame LARS, DP3, 5500 m² deck, 120,000 t deadweight, floating hose STS, 6500 m riser depth; CAPEX 353.1 MUSD; mean utility 0.56.

- esign III: Enclosed derrick, A-frame LARS, DP3, 5500 m² deck, 120,000 t deadweight, conveyor-boom STS, 6500 m riser depth; CAPEX 363.1 MUSD; mean utility 0.60.

Large deck area and high deadweight deliver outsized utility for both stakeholders. A support-vessel strategy for riser handling can free space and reduce specialization for the mining ship, which some operators may prefer. Full 6500 m capability increases flexibility to access any global deposit but adds complexity and space demands. Choice of STS method is context-sensitive; in rougher seas the floating hose may trade simplicity of transfer for the need to manage water content and dewatering interfaces on the shuttle bulk vessel.

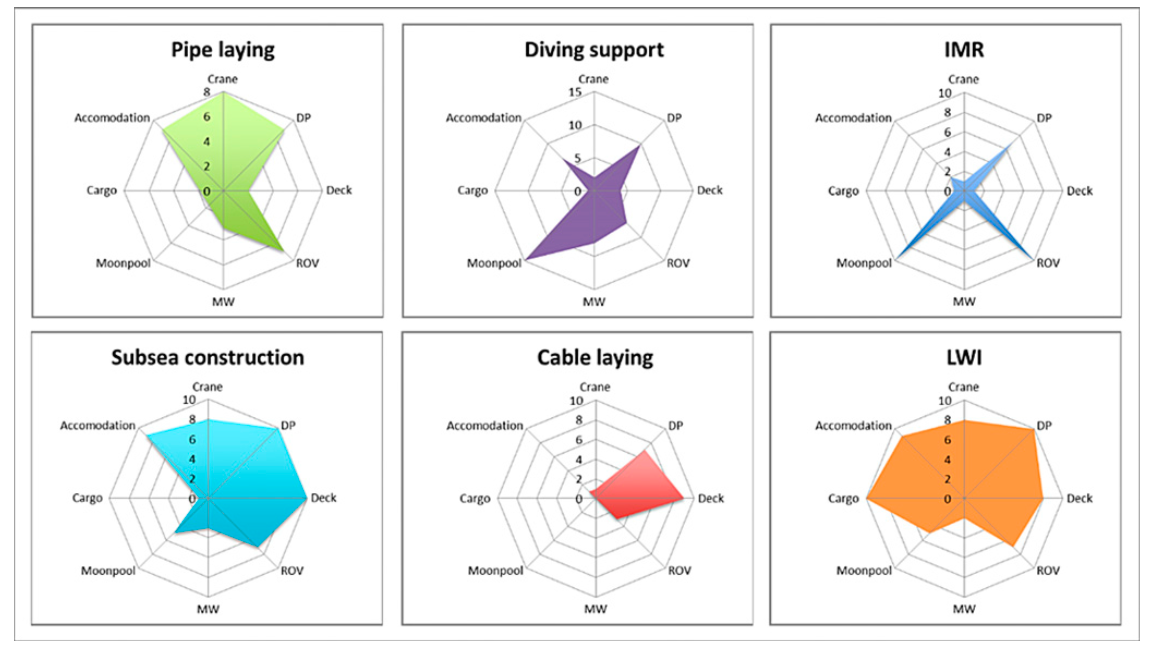

Figure 4 maps offshore special-purpose vessels and their main features, framing which systems (for example pipe racks, ROV hangars, LWI towers) migrate well into mining-ship configurations. This sets the technology menu that the tradespace explores.

Figure 8 plots the Epoch 28 tradespace and marks the Nautilus concept. Seeing that marker well off the Pareto front clarifies why the knuckle-point designs favor high deck area and deadweight and why tool selections with lower footprint earn higher utility.