Why Do We Need These Metals?

Every time you tap a screen, stream a video, or ride in an electric car, you’re using metals that don’t come in large, pure chunks — they’re scattered in tiny amounts across the planet.

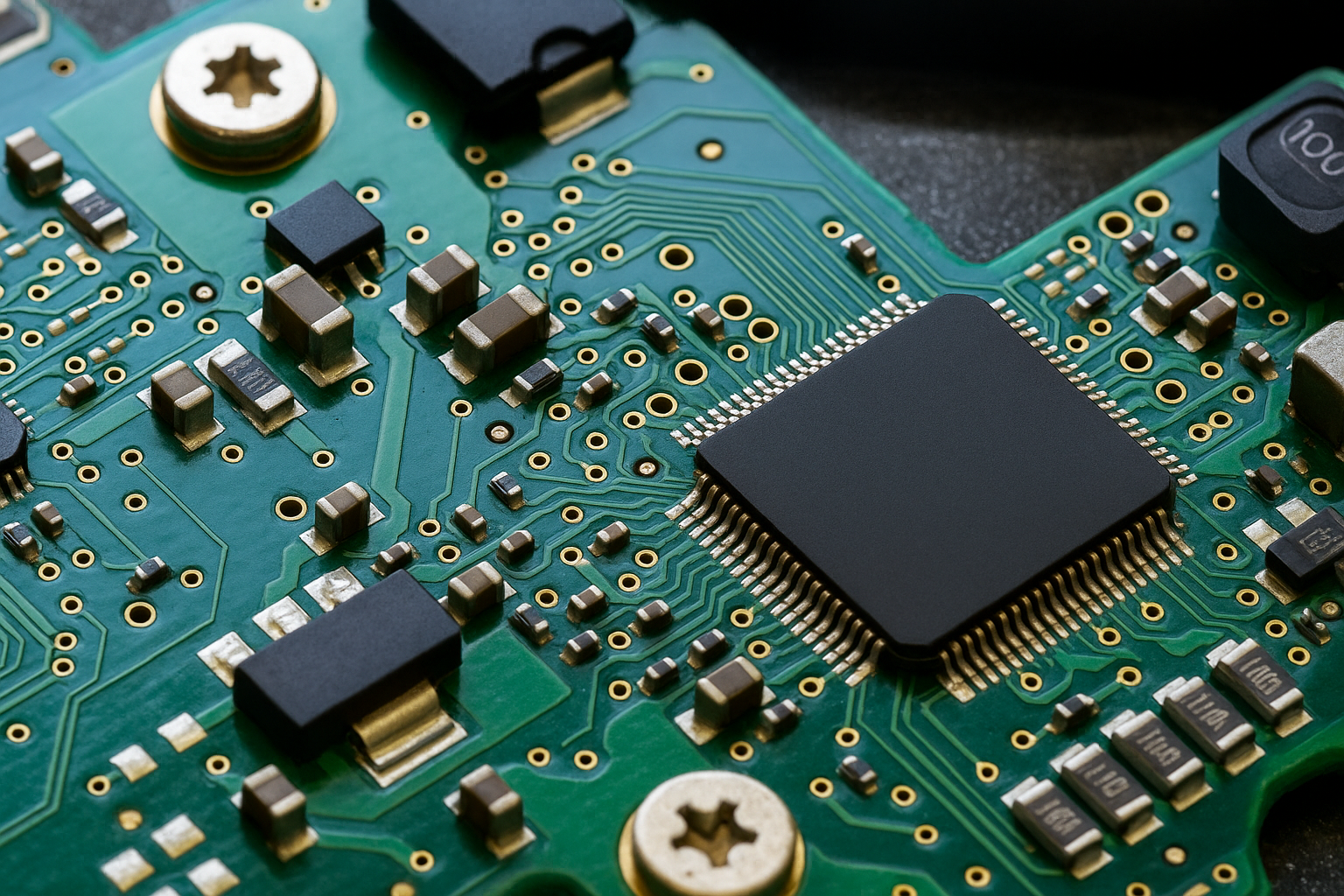

Inside a modern smartphone sit about 60 different elements, but a few are mission-critical. Copper carries electrical signals through threads finer than a human hair. Cobalt and nickel store energy in the rechargeable lithium-ion battery. Manganese stabilizes that battery so it lasts more charge cycles.

Rare-earth elements like neodymium and dysprosium power the phone’s tiny vibration motor and the loud but light speaker.

Now scale those needs up to a whole electric vehicle. A single EV battery can weigh half a tonne and swallow more than 35 kg of nickel, 10 kg of manganese and 6 kg of cobalt.

Wind turbines tell a similar story: each offshore unit the height of a skyscraper uses nearly four tons of copper wiring and magnets enriched with rare-earth metals to spin efficiently even in low winds.

Solar farms, data centers and high-speed rail all lean on the same periodic-table corner — copper for wiring, nickel for corrosion-resistant alloys, cobalt for energy density, manganese for toughness.

The world is shifting hard toward clean energy and digital everything. Agencies that track markets predict demand for battery metals could triple or quadruple by 2040, while many of the best land mines are aging, locked behind geopolitical tensions, or face stricter labour and land-use rules.

That growing gap pushes scientists and companies to search alternative sources, including the metal-rich nodules and crusts lying on the deep seafloor.

If harvested responsibly, these deposits could supplement — not replace — land mines, easing price spikes and bottlenecks that might otherwise slow the roll-out of electric cars, renewable power, and the devices we count on daily.